Description

Y-type Strainer, which is the filtration equipment which is to prevent impurities in the flow media from flowing into the back-end equipment. The strainer is usually installed before the Water Control Valves.

Pressure Reducing Valves and other equipment sensitive to medium cleanliness in order to prevent particulate impurities from entering into the back-end equipment to ensure the normal operation of the back-end equipment. The screen’s superficial area is 4 times the relative area, so as to achieve a low flow resistance, which ensures the screen from deformation when the differential pressure in the pipeline is too large.

▪ Drinking water-approved EPDM O-ring

▪ Potable water-approved epoxy coating, fusion bonded according to DIN 3476-1, EN 14901

▪ whole product WRAS approved for drinking water.

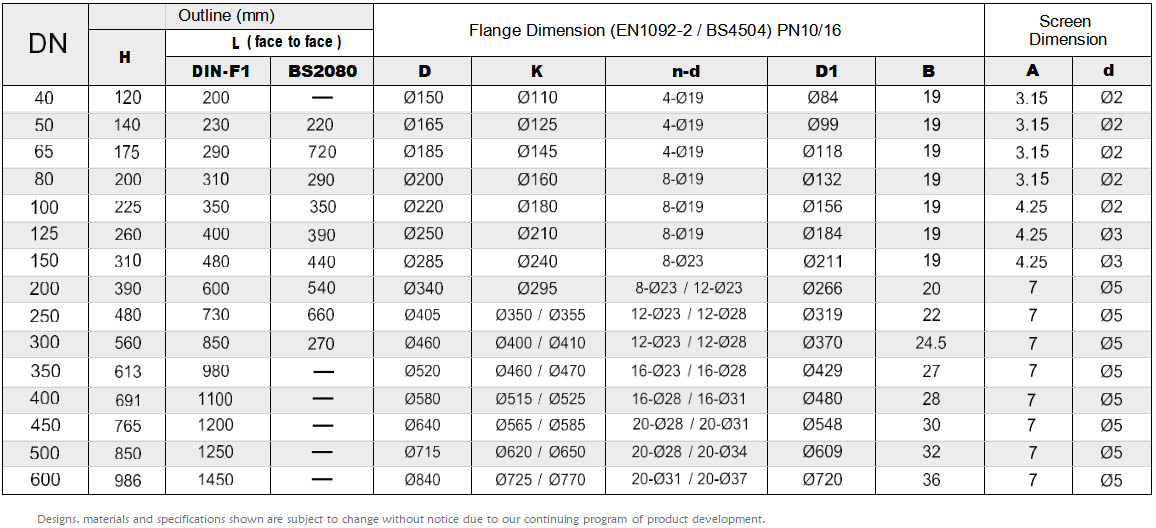

▪ Size range: up to DN600; Pressure range: up to 16bar

▪ Other sizes and pressures are available as a special request

▪ Double flanged ends

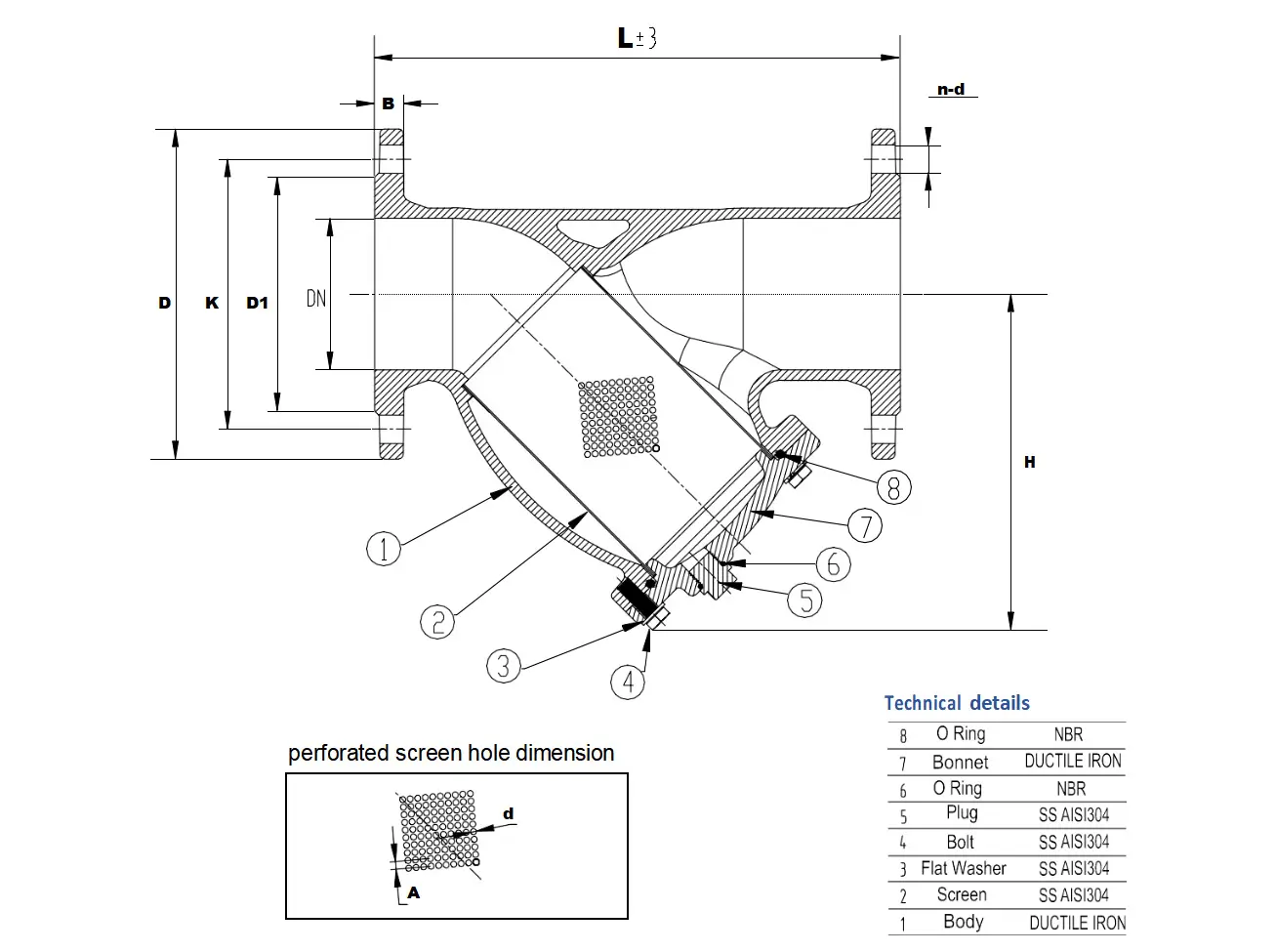

▪ Generally Cast ductile iron body, SS304 filter. Other materials are available as special requests.

▪ The Y-type strainer has the characteristics of advanced structure, small resistance, and convenient sewage discharge.

▪ The applicable media of a Y-type filter can be water, oil, and gas.

▪ Generally, the water net is 18~30 mesh, the air/gas net is 10~100 mesh, and the oil net is 100~480 mesh

▪ The screen’s superficial area is 4 times the relative area, so as to achieve a low flow resistance, which ensures the screen from deformation when the differential pressure in the pipeline is too large.

▪ The blind cover is designed with a drain plug which is convenient to drain the precipitated impurity. No need to disassemble the cover.

▪ Drinking water-approved EPDM O-ring

▪ Potable water-approved epoxy coating, fusion bonded according to DIN 3476-1, EN 14901

▪ whole product WRAS approved for drinking water.

▪ Face to face length conforms to DIN F1

Standards

Hydraulic tests according to EN-12266-1

Designed to BS EN558-1 / BS2080

Flanges to EN1092-2 / BS4504, PN10 / PN16

Service Fields

Water and neutral liquid applications

Main transmission pipelines

Irrigation system

Fire fighting

DIMENSIONS