Welded pipes are a type of steel pipe commonly used in various industries and applications. Unlike seamless pipes, welded pipes are manufactured by joining two or more pieces of steel together through a welding process.

Electric Resistance Welded Pipes (ERW) :

Electric Resistance Welded Pipes (ERW) are a specific type of welded steel pipe known for their high-frequency electric resistance welding process. In ERW, the edges of the steel strip or plate are heated to a melting point, and then they are rapidly pressed together to create a seamless bond. This method produces pipes with strong, consistent welds, making them suitable for various applications, including plumbing, construction, and structural projects. ERW pipes are known for their cost-effectiveness, as the process is efficient and less expensive compared to other manufacturing methods. These pipes typically offer good dimensional accuracy and a smooth surface finish. They come in a range of sizes and are readily available, making them a popular choice for many industries where reliable and budget-friendly piping solutions are needed.

- Carbon Steel: API5L GR A/B,X42,X52,X60/X65. Size range – 1/2″ to 24″.

- Stainless Steel: 304/L/H/LN, 316/L/H/LN/Ti/LMod, 310S/H, 317/L, 321/H, 347H/HFG. Size range – 1/2″ to 24″.

- (Super) Duplex Stainless Steel: S31803/S32205, S32750, S32760, S31500, S32001, S32003, S32304. Size range – 8″ to 24″.

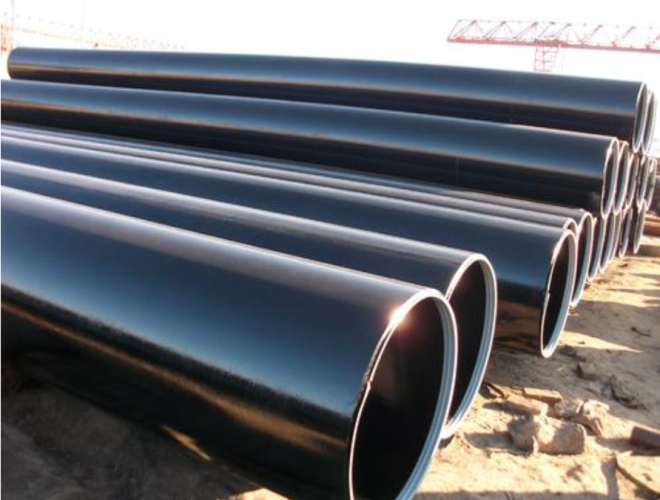

Longitudinally Submerged Arc Welded (LSAW)

Longitudinally Submerged Arc Welded (LSAW) pipes are a type of large-diameter, welded steel pipes commonly used in various industries, particularly in the transportation of fluids and energy resources. The LSAW process involves bending a steel plate or coil into a cylindrical shape and then welding along the length of the pipe using submerged arc welding. This method results in a strong, durable pipe with a longitudinal seam. LSAW pipes are preferred for applications that require pipes with large diameters and the ability to carry high-pressure fluids or gases, such as in the oil and gas industry. Their substantial wall thickness and resistance to corrosion make them suitable for challenging environmental conditions. LSAW pipes have the advantage of efficient production and offer excellent dimensional accuracy, which is essential in industries where precision is crucial for safe and reliable operations.

- Carbon Steel Line Pipes: API5L Gr B/ X42/52/60/65/70/80/90/100. Size range – 16″ to 64″.

- Carbon Steel Process Pipes: ASTM A53/333/671/672/691. Size range – 16″ to 64″.

- Carbon Steel Structural Pipes: API 2W 50 Z35 S1,S2,S5,S7,S8,S9 / 5L X52/ S355J2+N / S355G2+N. Size range – 16″ to 64″.

Helical Submerged Arc Welded (HSAW)

Helical Submerged Arc Welded (HSAW) pipes, also known as spiral submerged arc welded pipes, are a specialized type of steel pipe designed for applications that require large-diameter and high-strength pipes. The HSAW manufacturing process involves forming a steel coil into a helical shape and then welding it using submerged arc welding. This results in a continuous, spiral seam along the length of the pipe. HSAW pipes are known for their versatility and suitability for a wide range of applications, particularly in the oil and gas industry, water transportation, and structural projects. The spiral welding method offers excellent strength and allows for the production of pipes with larger diameters, making them ideal for projects that demand the transportation of substantial volumes of fluids or gases. HSAW pipes can withstand high pressure, harsh environmental conditions, and are often preferred when efficiency and reliability are paramount in the application.

Carbon Steel H SAW / SPIRAL PRODUCT PARAMETERS

- Outside Diameter: 18″ to 140″

- Wall Thickness: 6 mm to 25.40 mm

- Pipe Length (max): 18 meters

- Grade: Up to API 5L X-80